Supply Chain Services

- Home

- What We Do

- Supply Chain Services

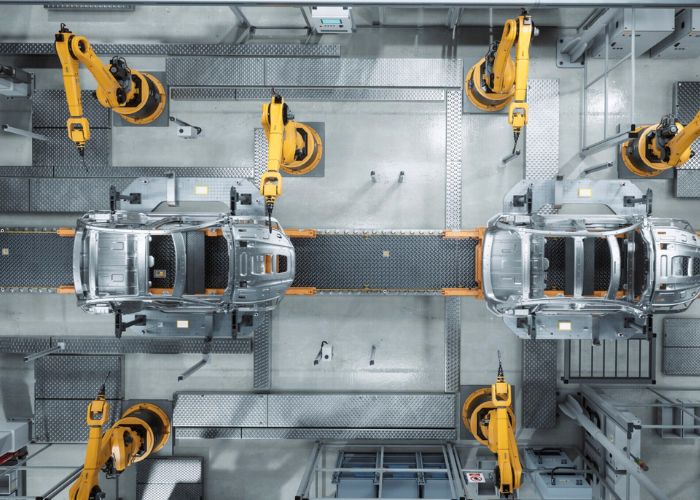

We aim to transform your procurement operations into a source of value, inspiration and disparity. With an all-inclusive understanding of business, products, technology, manufacturing and service support, there is no wonder why we are the ideal partner for your ventures. From identifying the right suppliers to establishing the process for prototyping and volume production, we help you support your strategic sourcing process at every step.

What we do

Supplier Quality Management

- Supplier Identification & Assessment (Source Evaluations)

- APQP and PPAP Support

- On-Going Supplier Quality Monitoring

- In-house Quality Assurance

- Supplier Audit

- RFQ Management & Negotiations

Should Costing

- Benchmarking Reports

- Raw Material Analysis

- Cost Study &

- Engineering Analysis on different product designs

- Should-Cost Models

- Manufacturing Process Study

- Negotiations Support

Strategic Sourcing

- Spend Analysis(PPV)

- Sourcing Strategies: Planning & Implementation

- Best Cost Country Sourcing

Prototyping Support

- Prototype Design & Analysis

- Establishing Mfg Process

- Selection of Prototype Technique

- Development of specific Quality Assurance Plans

- Testing & Validation of assemblies for concept & design

Volume Production Support

- Incorporate learning from development stage

- Identify materials for volume manufacturing

- Identify tooling for volume production

- Finalize commercials with identified suppliers

- Develop tooling

- Manufacturing Pilot Support

- Validate quality and performance of pilot lot

What sets us apart

- Knowledge and experience working with Global Automotive and domestic OEM’s

- Specialized engineers with expertise and understanding of different domains – 4W,Heavy commercial vehicles, 2W, 3W, 5W Electric vehicles

- Deep understanding of costing, local eco-system, work force, geographical and cultural pulse, and execution experience

- Executed System Level Should Costing programs for components of various commodities

- Knowledge & focus on PPAP and Quality tools for Supplier Quality Management

- Ecosystem of collaborating partners in various competencies and approved suppliers for prototyping in multiple commodities including plastics, aluminum, metal and ferrous.

Computer-Aided Design Portfolio

- CAD Visualization & Mock-up Models

- 3D Scanning & Surface Designs

- Ergonomics & Design Detailing

- 3D modelling, detail engineering and drawing quality

- Engineering Change Management and Non-Conformance Management

- Packaging Design

- Competitive Benchmarking

- Value Analysis & Engineering (VAVE)

- Product, components, tool, and fixtures

- Structural and Hydraulic systems

- Electrical Harness schematics

- Engineering change management

- Legacy Data Migration and Conversions

- Structural and Hydraulic systems,

- Electrical Harness schematics

Software utilized includes:

CATIA V5, Unigraphics NX, Pro-E / Creo, Autocad, Solidworks, VIS VSA, and VIS Mockup (digital buck).